NewSunka Technology

· Six advantages

-

Strong technical force

-

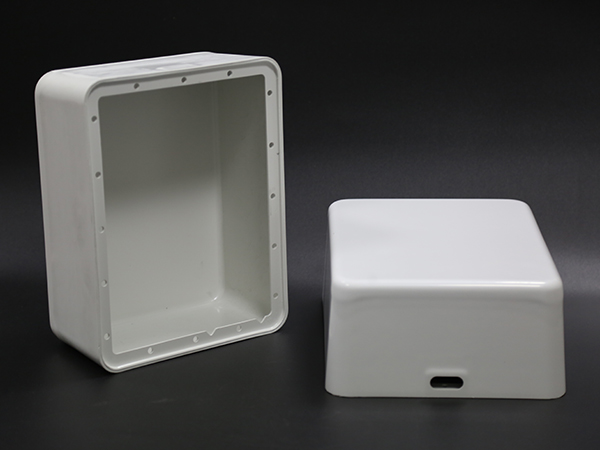

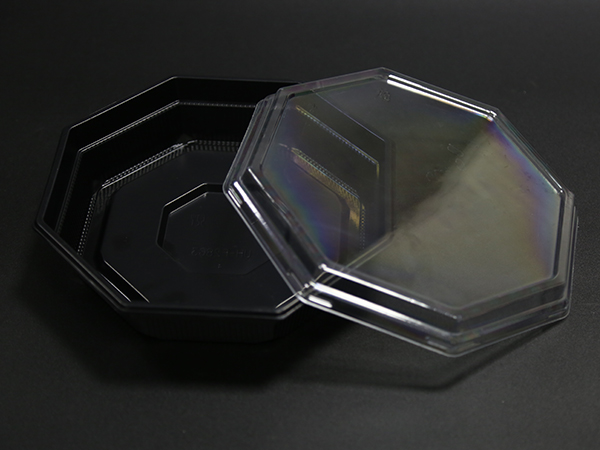

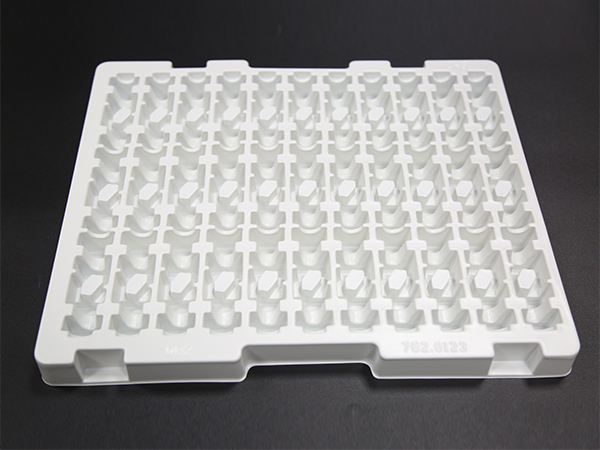

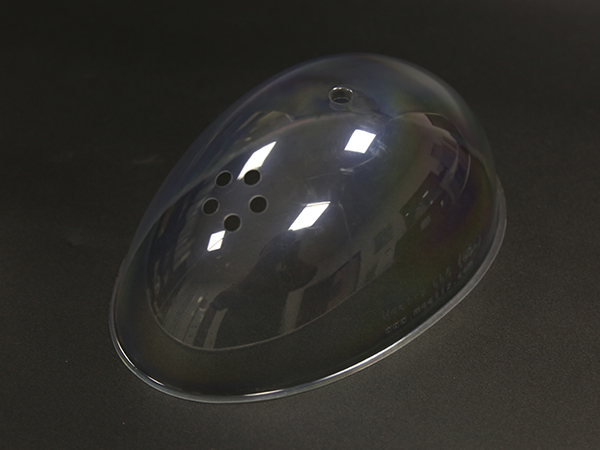

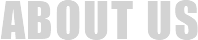

Mold, production integration

-

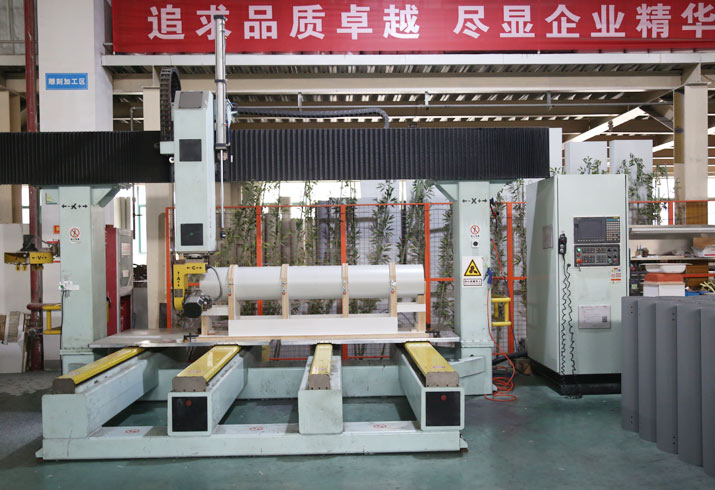

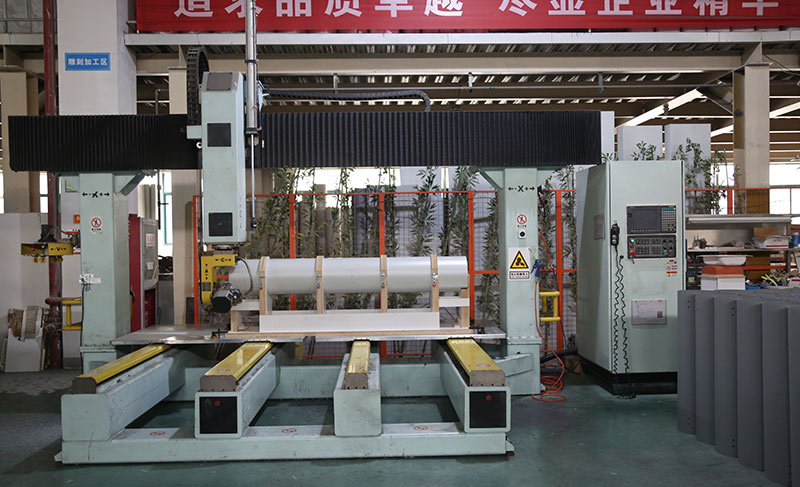

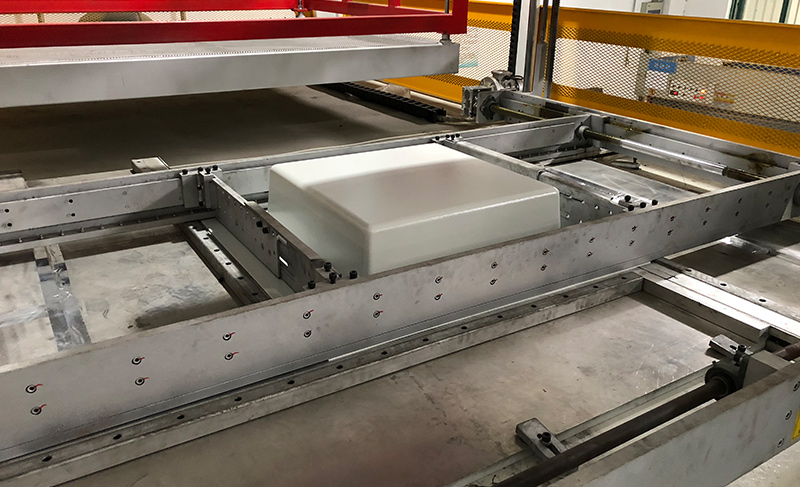

Advanced production equipment

-

Modified materials

-

Customized solution

-

Overseas business support

Strong technical force

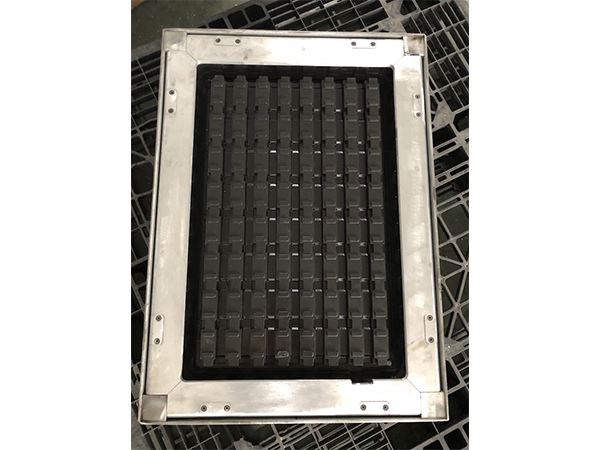

Mold, production integration

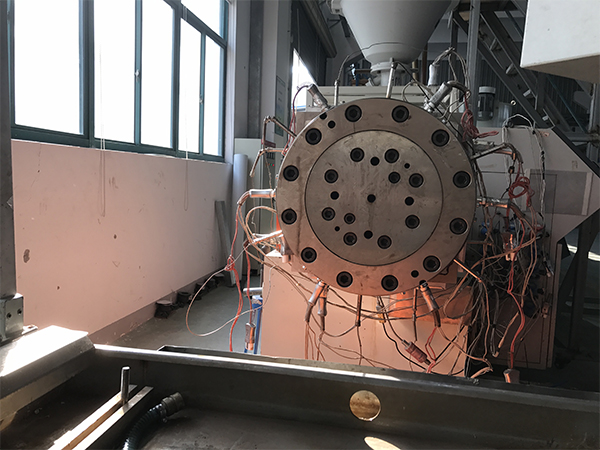

Advanced production equipment

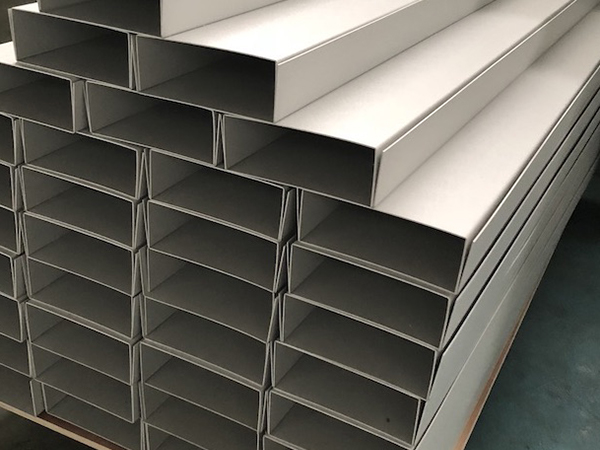

Modified materials

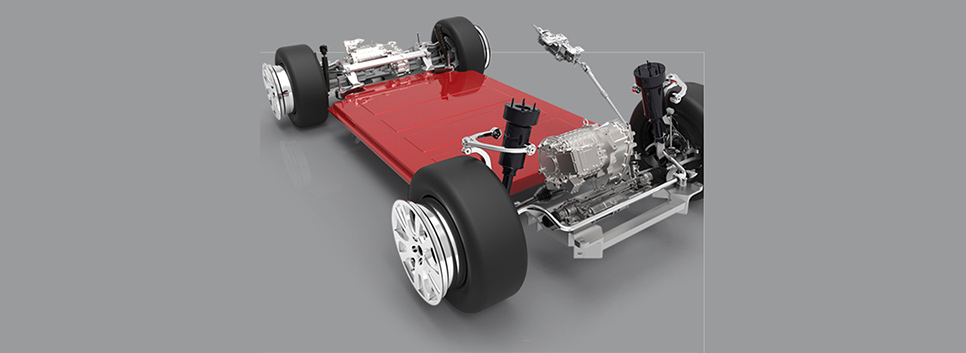

Tailor-made solutions

Overseas business support

中文

中文 English

English